FLUX 5S

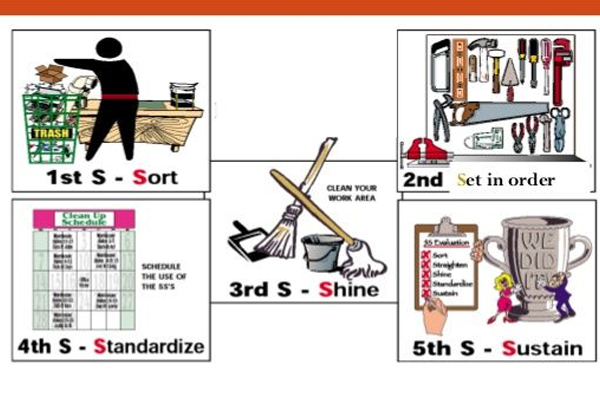

Implementing the 5S methodology in a sheet metal company involves five key steps: Sort, Set in Order, Shine, Standardize, and Sustain.

Sort (Seiri): Begin by removing unnecessary items from the workspace. This includes sorting through tools, materials, and equipment, and discarding or relocating anything not regularly used in the production process.

Set in Order (Seiton): Organize the remaining items to ensure efficient workflow. This involves arranging tools and materials in a logical order, labeling storage areas, and creating easy-to-access locations for commonly used items.

Shine (Seiso): Clean the workspace and equipment regularly. This step includes routine cleaning tasks and maintenance to keep the area tidy and to identify any equipment issues early.

Standardize (Seiketsu): Develop standards and procedures to maintain the first three steps. This could involve creating checklists, schedules, and visual guides that ensure consistent practices across the company.

Sustain (Shitsuke): Foster a culture of continuous improvement and adherence to the 5S principles. Regular audits, training sessions, and management support are crucial to sustain the implemented changes.

Overall, implementing 5S in a sheet metal company enhances productivity, reduces waste, and creates a safer, more organized work environment.