About us

Vincent Engineering

Vincent Engineering is a leading manufacturer of Sheet Metal Components and Sub-Assembly fabrication for the Automotive Industry. With nearly two decades of experience, Vincent Engineering has solidified its position as a trusted partner in the industry, providing top-notch solutions to esteemed clients such as TVS Motors, Royal Enfield, Tata Motors, Ashok Leyland, Maruti Suzuki, Renault-Nissan, and VST Tillers & Tractors. Situated in Dindigul, Tamil Nadu, India, we are proud to be an ISO 9001:2015 certified company, committed to delivering quality products with no compromise, ensuring On-Time Delivery and Zero PPM.

Our core strength lies in our ability to cater to a wide range of customer demands, offering Sheet Metal Components in varied RM grades such as IS 513D, IS 1079D, BSK46, SAPH440, SS 409L, IS 2062, E34, and more. Whether your requirements entail thicknesses ranging from 1mm to 12mm, we have the expertise and infrastructure to meet your needs.

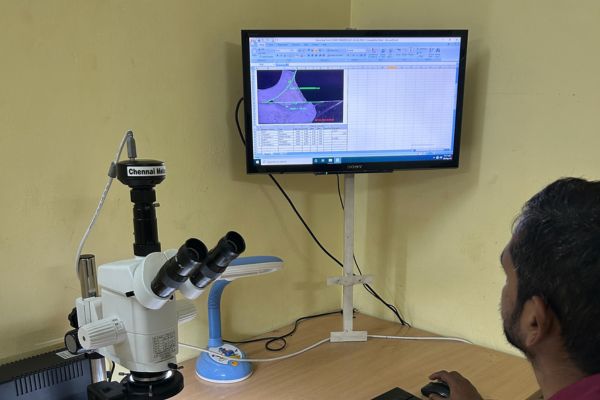

At Vincent Engineering, we take pride in being a single-source supplier for most of our sheet metal products, offering an extensive array of services including a robust In-House Tool Room facility, MIG Welding Fabrication, Special Purpose Machines (SPM), Welding Penetration Lab, Shearing Machine, and over 50 press machines.

Quality Excellence

- Commitment to delivering high-quality products that meet or exceed industry standards.

- Rigorous quality control processes to ensure precision and reliability in every component.

Customer Focus

- Prioritizing customer needs and building strong, long-term relationships through exceptional service.

- Providing customized solutions and responsive support to meet specific client requirements.

Innovation and Continuous Improvement

- Encouraging innovation and adopting the latest technologies and best practices in manufacturing.

- Fostering a culture of continuous improvement to enhance processes, efficiency, and product offerings.

Integrity and Transparency

- Conducting business with honesty, integrity, and transparency.

- Building trust with customers, partners, and employees through ethical practices and clear communication.

Safety and Sustainability

- Ensuring a safe working environment for employees and promoting sustainable practices.

- Minimizing environmental impact through responsible resource management and eco-friendly initiatives.

Precision and Reliability

- Emphasizing the importance of precision in manufacturing processes to deliver reliable and consistent products.

- Striving for zero defects and maintaining high standards of accuracy in all operations.

Teamwork and Collaboration:

- Valuing teamwork and fostering a collaborative work environment.

- Encouraging open communication and mutual respect among employees, customers, and partners.

Accountability and Responsibility

- Taking responsibility for actions and outcomes, and holding ourselves accountable to our commitments.

- Ensuring that all employees understand and adhere to the company’s standards and values.