LATHE MACHINE

- After asking the job from the production supervisor, the worker should go to his alloted machine and buy the equipments needed for setting from the store.

- Then x and z axis bed of lathe should well cleaned and oiled.

- While starting production, first 3 pieces are given to the q/c and inspected.

- Production can be start when the inspecrted dimension is correct. Whn it s not ok then resetting will be done.

- Gauge checking 100% should be done correctly.

- Incase of inproper gauge , causing nogo or other setting problems, the worker inform immidietly to the q/c

- The worker check the finishing of the piece, line marking, vibration

- Incase of causing any tool change or tool damage, the worker should inform to the q/c and change the tool.

- Preventiomn of rejection is very important. Incase causes any rejection the worker should inform to the q/c and keep in the rejection box.

- 3 pieces should be inspected at q/c at shift closing time.

- The worker should return all machine equipment to the tore after the shift closes.

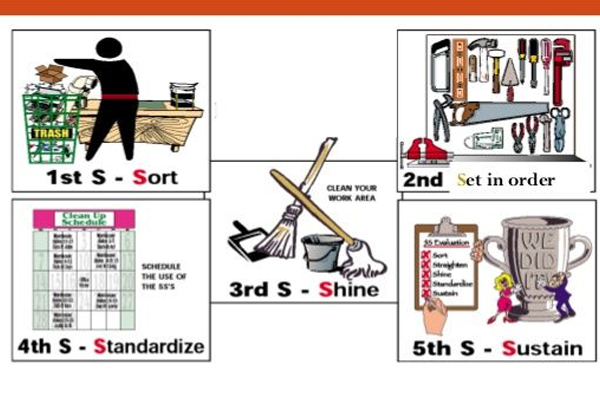

- The worker should clean his alloted machine and its surroundings after shift closes.