POWER PRESS

- After asking the job from the production supervisor, the worker should go to his alloted machine and buy the equipments needed for setting from the store.

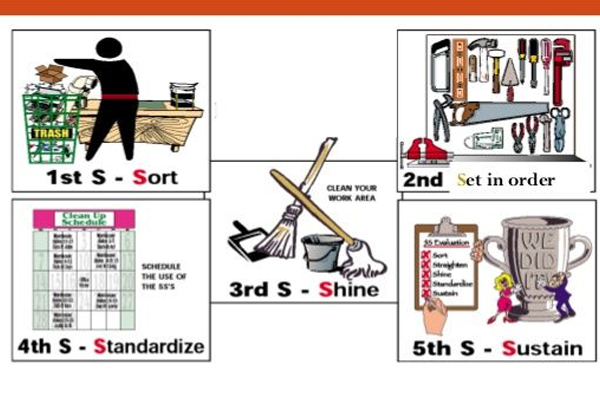

- The machine should well cleaned and lubricated before starting the production.

- while starting production, first 3 pieces are given to the q/c and inspected..

- If the inspection is not ok, then the production will be start after the dimension of the work pieces is corrected.

- The worker should strictly follow to wear the safety equipments while working on a machine.

- Miss feeding should be controlled. In case of miss feeding happened, the worker should inform to the q/c.

- Machine should be run after the tool is approved by the q/c

- Rejection should be controlled. If rejection occurs, then it should be informed to the q/c and it should be uploaded to n.c.r and the rejection piece should be kepty in rejction box.

- While finishing the production, first 3 pieces are given to the q/c and inspected.

- The worker should give the gauge at store after shift closes.

- Machines and its surroundings should be kept clean by the worker.